Early proponents of laser technologies believed they could push the frontiers of optical imaging and measurement techniques, from interferometry to radar. Yet lasers were not developed with a specific application in mind: they were a conceptual curiosity, contemporarily described as “a solution looking for a problem”. The benefits of that solution – its ability to produce light beams of monochromatic coherent radiation – quickly filtered through worldwide markets, and today’s laser applications permeate virtually every walk of life.

Modern Laser Applications

Modern laser applications vary from the commercial (barcode scanning, laser-based printing, optical discs, etc.) to the military and the municipal (guided munitions, fiber-optic communications, etc.). The ubiquity of laser applications worldwide is a result of the increasing versatility of the technology. Lasers are now available in a range of formats, exploiting the underlying technique of light amplification by stimulated emission of radiation (LASER) to generate coherent beams across the ultraviolet, visible, and infrared (UV-Vis-IR) spectrum of light.

More important for cutting edge laser applications is the ability to generate intense laser beams with extremely short pulses and high peak pulse powers. Femtosecond lasers produce surgically-precise beams of radiation that pulse on an order of femtoseconds (10-15 seconds). Industrial solid-state lasers with an average peak power of 1-20 Watts are widely employed for micromachining applications, but the thermal side effects of this can mitigate the precision required for complex components and materials. This is particularly prevalent in brittle and high-hardness materials like glass and sapphire, which further complicate laser micromachining due to their transparency at Vis-NIR wavelengths.

Laser Applications with Transparent Materials

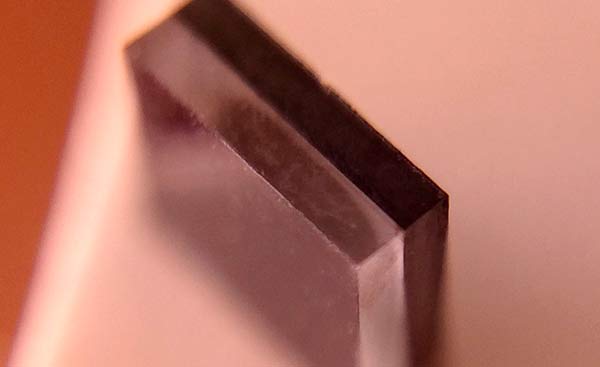

Glass bonded to CTE-matching silicon by IMRA laser DX series laser source.

Lasers with shorter pulses have demonstrated improved precision in terms of depth of penetration and minimization of heat dissipation through the periphery of the material underneath the laser spot.

Read More: 4 Uses of Femtosecond Lasers

With transparent materials like glass or translucent polymers, femtosecond laser pulses exhibit such a high peak intensity that highly localized non-linear absorption is induced. This unique process ensures that absorption occurs exclusively at the internal focus point of transparent materials with inhibited propagation of process heat through the surrounding material. An immediate benefit of this is a significant reduction of the heat-affected zone (HAZ); a common side effect of laser ablation.

Femtosecond laser technologies have unlocked a plethora of new laser applications with transparent materials, including:

- Ablation and microfabrication of glass, transparent polymers, sapphire, diamond, etc.

- Direct drawing and bulk internal selective laser etching of transparent bodies

- Glass-to-glass welding and bonding of other transparent materials

IMRA Laser Applications

IMRA is a specialist in ultra-short wavelength pulsed laser technologies, championing the development of fiber-chirped pulse amplification (FCPA) laser micromachining for high-technology applications. We can assist in various laser applications with our FCPA and Femtolite series of laser micromachining technologies.

If you would like more information about the intricacies of modern laser applications, read our recent blog post: What Does Cold Ablation Really Mean? Otherwise, contact a member of the IMRA team today with any questions.