IMRA is a pioneer in applying femtosecond lasers to a variety of commercial applications. Supported by years of cumulative expertise in materials processing, IMRA has made significant contributions to laser-based diamond tool machining. Our Application Development Center (ADC) is well-equipped with a range of workstations, with femtosecond-pulsed lasers in near-infrared (NIR), green, and ultraviolet configurations. This wide range of flexibility has helped us develop unique solutions for some of the toughest material processing applications in the industry.

Where IMRA Fits into the Diamond Tool Machining Process

Diamond is one of the hardest materials ever discovered. This makes it highly useful as an abrasive and a cutting edge for many demanding machining applications. Many of these applications require single-crystal synthetic diamond crystals to be embedded in machine tool bits, and for these crystals to be faceted and cut so as to present a sharp edge that is used for machining other materials. Understandably, the formation of these sharp edges is extremely difficult. In fact, diamond machining via mechanical means is virtually unfeasible without using other diamond-based cutting tool bits and abrasives.

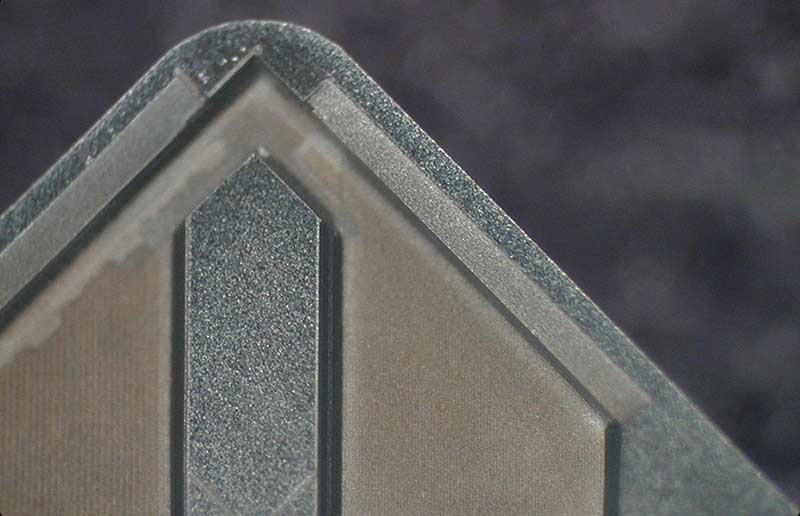

FCPA laser processed a chip breaker into a cutting tool made of diamond.

Laser-based diamond tool machining is an alternative and novel method to diamond tool machining by mechanical means. In the past, the optical transparency of diamond has prevented effective laser-based processing of diamond tool bits. However, the onset of femtosecond lasers has enabled the cutting and drilling of diamond and has reinvigorated interest in the processing of diamond for ultra-precision applications and other industrial uses. Such applications of femtosecond lasers are now providing solutions in markets that were previously not addressable. For example, femtosecond lasers are used in the preparation of tools for oil exploration. These tools are difficult and expensive to manufacture because they incorporate the hardest possible materials, such as steel, tungsten, and diamond, to ensure maximum tool longevity.

Read More: A Guide to Femtosecond Lasers

Another demanding application is the preparation of diamond tool bits for single-point diamond turning (SDPT). SDPT is a well established high-end machining technique for generating precision and pristine metallic optical surfaces, such as aspherical reflectors for high power applications. Using diamond-tipped tool bits, SDPT can generate accurate surface profiles with tolerances within just a few nanometres (nm). This level of accuracy and surface quality is enough to routinely and reliably satisfy the stringent quality demands of optics that is intended for use in a range of high-value markets, including moulds for precision optics for consumer and telecommunication electronics.

Benefits of Diamond Tool Machining with Femtosecond Lasers

At IMRA, we have demonstrated the theoretical benefits of using femtosecond lasers for diamond tool machining in a practical sense, from both operational and fiscal perspectives. These include:

- Higher precision micromachining due to a sharp reduction in thermal side-effects, debris generation, recasting, or burring.

- Reduced collateral damage of transparent workpieces.

- Unique ability to machine materials that are transparent to the laser wavelength.

- Absolute precision in surface nanostructuring for complex components.

These outstanding characteristics have opened a world of complex applications for laser workstations based on ultrafast FCPA technologies. Among those is the generation of complex, hard-wearing cutting tools for diamond machining. Using our proprietary technology, we have successfully manufactured chip breakers to optimize the cutting point and debris discharge in demanding diamond tool machining applications. This has proven benefits in terms of reducing tool wear and improving the productivity of the cutting machine.

Diamond Tool Machining with IMRA

IMRA specializes in femtosecond fiber lasers, with a focus on reaching new capabilities and realizing novel applications of this pioneering technology. If you would like more information about how we can assist your diamond tool machining operations, simply contact a member of the team today.