Laser material processing refers to a growing school of techniques that use high-energy laser light to modify the surface of materials. It is one of the most common, and highest value, laser applications available to engineers, providing the means to rapidly machine an array of materials with outstanding repeatability down to the sub-microscale.

In this blog post, IMRA will explore some of the key material processing laser applications while offering brief insights into the underlying principles of ablation and surface modification.

Background to Laser Material Processing

The history of laser technology dates to the early 20th Century and Einstein’s prediction of the phenomenon of stimulated emission. This was not physically demonstrated until 1950 when Nobel Prize-winning physicists successfully stimulated the emission of microwaves based on new quantum theory. Further development of this revolutionary technology enabled researchers to amplify light via stimulated emission, creating coherent beams of narrow light which were dubbed lasers.

In a comparatively short period, the field of laser applications grew significantly. Among those early developments were two clear front-running successes: optical range-finding, and material processing.

Laser-based material processing today is the most common and highest value application available to engineers. It provides the means to rapidly machine an array of materials with outstanding repeatability down to the sub-microscale. Solid-state lasers with a synthetic ruby crystal gain medium, which produced coherent pulses of visible light at an approximate wavelength of 694 nanometres (nm), were the first laser-based tools used in industrial material processing. They are not widely used owing to their relatively low efficiency and pulse repetition rates, but they remain one of the main types of lasers used to drill diamond.

Despite enormous development in laser-based materials processing, today, there is still no single laser that can process every material and produce every shape and form as required by individual applications. Ultrafast pulsed lasers are the first true step towards a laser technology that can achieve just that. A single ultrafast pulsed laser can process various materials, even those that are not absorbing, which makes the technology immensely versatile and economically advantageous.

List of Material Processing Laser Applications

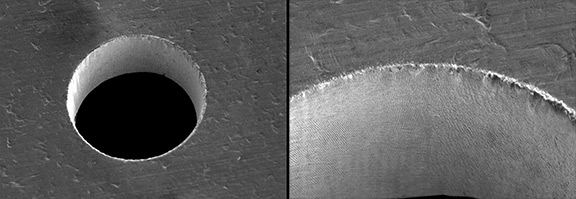

Today, ultrafast pulsed laser technologies with repetition rates on the order of pico- and femtoseconds set the benchmark for precise cutting, drilling, and etching of materials with nanoscale levels of precision. Ablation remains the underlying mechanism for each of these processes, but the parameters of laser ablation can be finely tuned by adjusting the wavelength, pulse duration, spot size, peak power, and other important processing parameters.

Read More: A Guide to Femtosecond Lasers

IMRA fiber lasers have been used in research applications typically serviced by long-standing titanium sapphire (Ti:Sapphire) lasers, and increasingly in industrial and manufacturing sectors. This partially comes as a result of their finely-tailored laser parameters and robust, production line-ready formats. Consequently, IMRA products are now able to satisfy the demands of an increasingly diverse range of material processing laser applications.

The FCPA DE µJewel Series of ultrafast lasers is uniquely prepared for a raft of materials processing applications, including:

- Thin-film ablation

- Micro-processing

- Selective laser etching

- Glass welding

- Wafer processing

The FCPA DX µJewel Series is employed in similar research and development (R&D) areas but is additionally suited for marking applications (also called etching). The FCPA DH50K meanwhile enables applications as varied as:

- Thin-film patterning

- Micromachining and microtexturing

- Transparent material processing

- Metal surface treatment

- Hard material processing

Material Processing with IMRA Ultrafast Lasers

With a history of global innovation in the field of ultrafast fiber laser technologies, IMRA specializes in fiber-chirped pulse amplification (FCPA) for material processing and other high throughput laser applications. Our strong ongoing product development has yielded two unique product lines under the FCPA and Femtolite brand names.

For more insight into other laser applications that IMRA products excel in, read our recent blog post Laser Applications: Transparent Materials Processing

If you would like to learn more about which of our advanced series suits your material processing needs, simply contact a member of the IMRA team today.