With a broad range of high-analytical key performance indicators and the durability to withstand rugged operating conditions, femtosecond fiber lasers can satisfy the variable demands of users across an extremely broad market cross-section.

Arguably, there are three primary application areas for femtosecond fiber lasers today: clinical settings, industrial settings, and working environments that straddle the boundary between the two. This ability to operate effectively in traditional scientific contexts and in rugged conditions alike is an important driver behind the large-scale adoption of innovative optical technologies like femtosecond fiber lasers.

X-ray fluorescence (XRF) spectroscopy, for example, was developed as a high-end benchtop solution for scientific research. Within decades, it was developed into a portable, practical tool for process and quality control in some of the toughest working conditions on earth (foundries, quarries, etc.). Femtosecond fiber laser technology is immature – relative to the likes of XRF – but it already boasts the necessary durability to justify its application in real-world working environments.

- Transparent Materials Processing

Femtosecond fiber lasers are outstanding in the field of transparent materials processing, offering manufacturers the opportunity to finely-tune the ablation and welding of glass with unmatched mitigation of thermal side-effects.

Learn more Laser Applications: Transparent Materials Processing

- Microfabrication

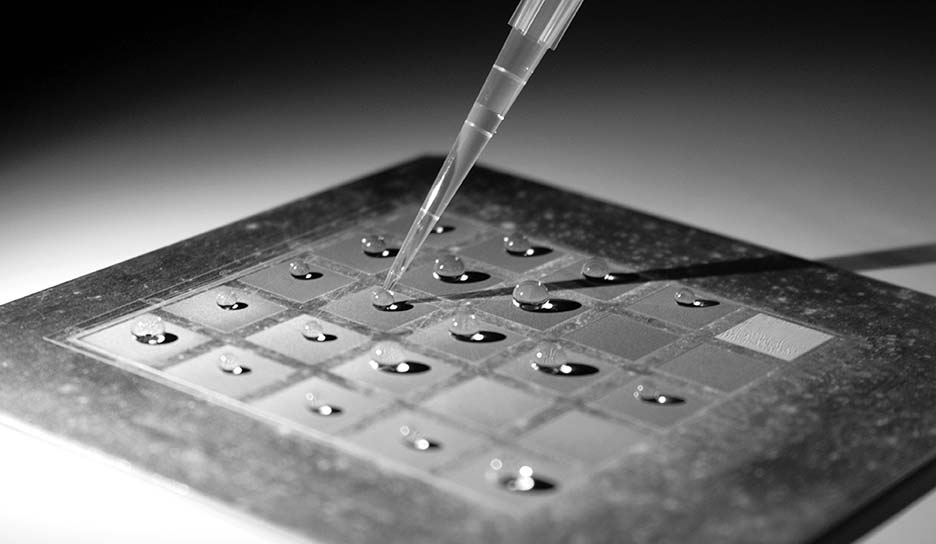

Laser-based microfabrication and microstructuring are now widespread, with femtosecond fiber lasers revolutionizing processes by providing surgically precise ablation at smaller scales than ever before. With unrivaled mitigation of the heat-affected zone (HAZ) and wide compatibility with various materials, femtosecond fiber lasers are increasingly trusted to engineer high precision components for critical markets.

Furthermore, applications of femtosecond lasers are broadening. Those encompass manufacturing of tiny parts, from components for watches to medical-related sensors, and also larger more mature industries such as automotive engine components.

For a more detailed insight into which materials are suitable for femtosecond microfabrication, read our previous article Polymer Machining with Femtosecond Lasers.

- Imaging and Spectroscopy

Femtosecond fiber lasers are naturally at home in imaging and spectroscopy applications, owing to their high peak powers and ultrafast dynamics. IMRA Femtolite fiber lasers are built around a choice of wavelength ranges (805, 810, or 1620 nm) in the near-infrared (NIR) wavelength range. This provides the groundwork to assist in a range of advanced imaging applications, from multiphoton fluorescence microscopy to terahertz imaging.

- Nanoparticle Generation

Nanotechnology has experienced growth in recent years with numerous novel techniques evolving to support the controlled synthesis of nanostructures and nanoparticles. In particular, nanoparticle generation in liquid using pulsed laser ablation is one of the cleanest methods to have emerged, and femtosecond fiber lasers are clear frontrunners in this area.

In a recent publication, spherical germanium (Ge) particles with nanoscale geometries (20 – 80 nanometres) were generated using femtosecond fiber lasers and a simple aqueous hydrochloric acid (HCl) solution, exemplifying the technology’s ability to cleanly conjugate nanoscale structures.

Femtosecond Fiber Lasers from IMRA

IMRA is one of the leading proprietors of femtosecond fiber laser technologies, with a suite of fiber lasers available for unique user requirements. The FCPA Series is a compact solution engineered specifically for industrial applications, while the Femtolite Series was designed for ease of integration into existing systems.

If you would like more information about the range of femtosecond fiber lasers from IMRA, simply contact a member of the team today.